Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

For much of the 20th century, asbestos cement sheets provided builders with a rugged solution for simple roofing and siding projects. While these products were cheap to manufacture and buy, their true cost emerged years later in the form of deadly asbestos-related illnesses.

Most asbestos cement sheets are used to make roofing, but they are also used for siding and flooring. Asbestos cement products make up about 90% of international asbestos product production.

While asbestos cement sheet production in the U.S. ended in the 1980s, it remains legal to import the product from other countries.

Fibrous asbestos cement is more durable than drywall and easier to work with than concrete. It has numerous applications in construction, including use as roofing and siding. Today in the U.S. the fibers in cement sheets are usually made of cellulose, a substance found in plants. For nearly 80 years they were primarily made with asbestos.

Homes, military bases, public buildings, industrial settings and job sites used these sheets. Asbestos cement sheet was once synonymous with “fibrous cement sheet.” It has also been generically called “AC sheet” and “fibro.”

U.S. companies stopped manufacturing these types of asbestos products. Asbestos cement sheets are still popular building materials in developing nations such as India and China. These products are dangerous because with age and damage, they become friable, or easy to crumble. This damage makes them likely to release asbestos fibers.

Corrugated Asbestos Sheets

Fibrous cement created an easy and affordable alternative to corrugated metal panels. Corrugated asbestos sheets were used in the roofing and siding of all types of buildings, especially in factories and on farms.

Asbestos Flatsheet

Fibrous cement is much more water-resistant than drywall. Flat sheets of asbestos cement found their way into the interiors of homes and businesses as walls and underlayment for flooring.

Asbestos Board

Also known as cement wallboard and asbestos millboard, asbestos cement boards were produced in sheets. They were used as a fireproofing material around boilers, heaters and wood stoves. Asbestos board was also used for automobile hood liners and as gaskets and washers in electrical applications.

Asbestos Lumber

Also called asbestos cement sheathing, “asbestos lumber” was not made out of wood at all. Instead, it was marketed as a superior alternative to wood. It was fireproof and electrically nonconductive, yet still soft enough to be worked like natural lumber. Asbestos lumber was used as a base for roofing and siding materials such as shingles and false brick facing.

Asbestos products are notoriously difficult to identify visually. The best approach is to have a suspicious product tested. Workers should assume that older corrugated roofs and flatsheets will likely contain asbestos.

American brands of asbestos cement sheets include:

| Manufacturer | Brand |

|---|---|

| Celotex | Careycel Insulated Sheathing, Careystone Corrugated Asbestos Cement, Careystone Flat Asbestos Cement |

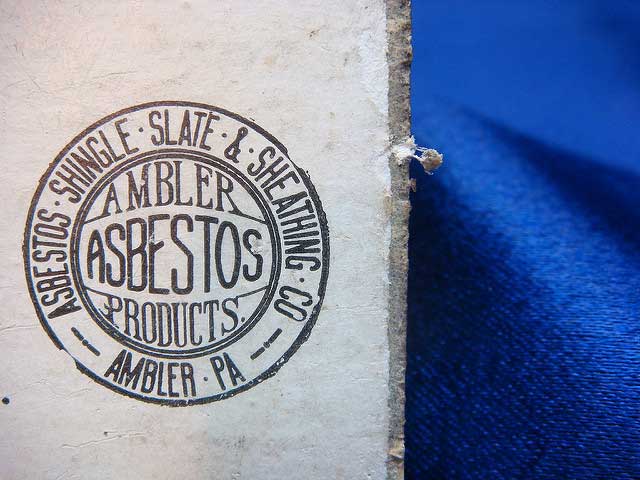

| Keasby & Mattison Company | Ambler Asbestos Corrugated Sheathing, Ambler Corrugated Roofing and Siding, Century Asbestos Corrugated Roofing |

| GAF Corporation | Panelstone Asbestos Cement Sheeting |

| National Gypsum Company | Gold Bond Corrugated Roofing, Gold Bond Cement Flatsheet |

| Johns Manville | Transite Corrugated Roofing and Siding |

Other companies that manufactured asbestos cement sheets include:

These companies are among the most notorious companies known to make asbestos products. Asbestos cement sheets were a popular product, and many manufacturing companies made them in the 20th century.

Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

Manufacturing and working with asbestos cement sheets may lead to asbestos exposure. Exposure causes diseases such as mesothelioma, lung cancer, asbestosis and other health problems.

Manufacturing and working with asbestos cement sheets may lead to asbestos exposure. A 2022 research study found that 52.4% of samples from asbestos cement sheet factories across Vietnam contained asbestos dust in the air.

A research study from 2009 in Thailand showed that people who worked with asbestos cement sheets (a type of roofing) were exposed to a lot of asbestos. People involved in making the sheets also had high exposure when they handled bags full of raw asbestos fibers.

Exposure to asbestos from cement sheets is known to cause asbestos-related diseases such as:

If you used to work with asbestos cement sheets, it’s important to pay attention to your health. Look out for signs of breathing problems or stomach issues such as trouble taking in air or a swollen belly. If someone finds out they have an illness related to asbestos, they should talk to a doctor who knows about the latest treatments available.

People at risk of exposure from asbestos sheets include:

The installation, repair and demolition of asbestos cement sheets generated toxic dust. Inhaling asbestos dust over time puts people at risk of developing lung cancer and mesothelioma.

Factory workers and tradesmen have sued companies that produced asbestos cement sheets. These individuals were granted money for any harm they experienced due to their asbestos exposure.

In the United States, companies that make asbestos products can be taken to court if their products cause illnesses. These corporations knew about the risks and still chose not to protect work handling asbestos. Documents from inside the companies have proven this to be true.

When companies that used asbestos went bankrupt, they had to create trust funds. To reorganize their finances, these companies had to set up trusts for people affected by asbestos.

Corporate mergers left Armstrong World Industries responsible for all the asbestos exposure caused by Keasby & Mattison’s asbestos products. This included its asbestos cement sheets. Today claimants can seek asbestos compensation from the Armstrong World Industries Asbestos Trust. It has paid out hundreds of millions of dollars in claims since 2006.

It is important to speak with a qualified mesothelioma attorney to learn about the lawsuits and trust funds your case may be eligible for. You may also qualify for other forms of compensation such as VA claims, treatment and travel grants, workers’ compensation and Social Security Disability Insurance.

We have more than 50 years of combined experience helping mesothelioma patients.

Chat NowThe U.S. Environmental Protection Agency has placed asbestos corrugated sheets in Category II. This means that the material should be removed carefully before any demolition or renovation takes place. Over time and with damage, this material can become friable, making it dangerous to handle.

If the material is not broken, it can be taken down by pushing the nails all the way through or cutting off their heads. If asbestos sheets are damaged, there are special rules that must be followed.

It is important to take off each sheet of corrugated material or sheathing at once and keep it wet so that asbestos particles do not get into the air. All materials must be thrown away in a way that follows your state’s laws. Generally, it is recommended for licensed professionals to remove any items containing asbestos.

In the 1980s, people started to file lawsuits against companies because of health issues caused by asbestos. This made manufacturers stop making products with asbestos in the United States. But, even though it has a bad reputation in some countries, you can still find and buy products with asbestos online from other parts of the world. You are also allowed to import these products into the U.S.

In the 1950s, the National Gypsum Company added a type of roofing called corrugated asbestos to its Gold Bond products. This made it popular with people who built homes, farms and factories.

In 1907, Keasby & Mattison was one of the first businesses to make corrugated asbestos sheets. They would press a combination of cement, water and chrysotile asbestos between metal plates with lots of pressure to get rid of extra water and form a corrugated pattern. This looks like many lines running together that give strength to the cement sheets. K&M named their brand after Ambler, Pennsylvania where their factory was located.

This company was known for its lightweight, easy-to-install roofing and siding products. It also boasted that the materials were fireproof, attractive, and durable. The first customers included a business in Massachusetts, one in Pennsylvania, and another in Canada. When a fire broke out in one of the Bell mills, the asbestos siding and roofing reportedly contained the blaze, backing up K&M’s claims.

Recommended ReadingYour web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Whitmer, M. (2025, January 13). Asbestos Cement Sheets. Asbestos.com. Retrieved March 27, 2025, from https://www.asbestos.com/products/asbestos-sheets/

Whitmer, Michelle. "Asbestos Cement Sheets." Asbestos.com, 13 Jan 2025, https://www.asbestos.com/products/asbestos-sheets/.

Whitmer, Michelle. "Asbestos Cement Sheets." Asbestos.com. Last modified January 13, 2025. https://www.asbestos.com/products/asbestos-sheets/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Sean Fitzgerald, PG, is a research geologist specializing in asbestos environmental studies.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.