Based on Your Reading:

Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

Workers whose jobs involve being on or near automobiles face an increased risk of mesothelioma from exposure to asbestos-containing auto parts. Automotive garages, auto repair shops, gas stations, bus stations and truck stops are sources of this type of asbestos exposure.

Written by Daniel King | Edited By Fran Mannino | Last Update: September 4, 2024

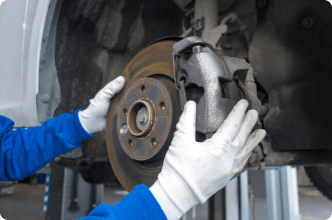

Asbestos has been used in a wide variety of auto parts. Examples include brakes, clutches, hood liners, gaskets and heat shields.

Historically, drum and disc brakes were manufactured with 35% to 60% asbestos. While most car manufacturers stopped making asbestos-containing brake pads in the 1990s, it remains legal in the U.S. to sell aftermarket asbestos-containing auto parts, and many brake and clutch parts, especially in older vehicles, continue to contain up to 35% asbestos.

82%

The percent of auto mechanics who are frequently exposed to asbestos.

Source: American Journal of Epidemiology

A 2018 study estimates 730,000 documented workers in the U.S. are at risk of asbestos exposure from brake repairs alone. It also estimated millions of do-it-yourself mechanics are also at risk of asbestos exposure.

Hobbyists working on older cars are especially at risk because older cars are more likely to contain asbestos parts than newer cars. Both professionals and do-it-yourselfers are at an increased risk of developing mesothelioma.

A wide variety of asbestos-containing products have been used in automotive transportation. Contaminated parts have been used on every type of vehicle. This includes cars, trucks, motorcycles, buses, trains and military vehicles. Asbestos brakes and clutches, which have been a primary source of exposure, were also used in elevators and other types of transportation machinery.

In addition to insulation, asbestos gaskets were widely used in automobiles. Different types of gaskets used in vehicles include rope and sheet gaskets. They were used on cylinder heads, oil pans, manifolds and pumps. Two name-brand asbestos gaskets used in engines include Felbestos and Shimbestos.

It’s very common for mesothelioma patients to have at least some exposure that falls in the category of auto mechanic. This isn’t always the patient’s main occupation. I have found a lot of patients did some of their own auto work, especially the changing of brake pads.

Workers were exposed in auto assembly plants, repair shops and supply stores. Trains, bus stations, truck stops and auto part manufacturing plants exposed workers. Even toll road collectors are at an increased risk of developing asbestos-related diseases. That’s because of repeated exposure to asbestos brake dust.

Automotive Occupations at Risk of Asbestos Exposure

Do-it-yourselfers who enjoy working on cars are at high risk of asbestos exposure. They often don’t have proper protective equipment and may be unaware of protocols to reduce exposure.

Mesothelioma has been documented in auto mechanics, their wives and children. Individual case reports have described cases of mesothelioma among auto mechanics. Secondary asbestos exposure happens when workers bring fibers home. This type of exposure can cause mesothelioma in spouses and children.

I first came in contact with asbestos through the brakes of cars. I also used to be a mechanic for our household, so I would disassemble cars and came into contact with asbestos.

Population studies have examined the risk of pleural mesothelioma among professional auto mechanics. A 2018 study found an increased incidence of mesothelioma in auto mechanics, citing more than 400 cases in the medical literature.

A 2001 study reported a 10-fold excess of mesothelioma cases among auto mechanics. In 1985, a U.S. Environmental Protection Agency exposure study confirmed brake and clutch repair work resulted in asbestos exposure levels far exceeding the ambient air levels the Occupational Safety and Health Administration have set.

Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

The U.S. Environmental Protection Agency has issued best practices for brake and clutch repair workers that complement Occupational Safety and Health Administration laws. The EPA’s recommendations aim to help both professional and at-home mechanics limit asbestos exposure, while OSHA’s laws only apply to professional workers.

Best Practices for Auto Mechanics

The EPA strongly recommends professionals handle all brake and clutch repair work. Professional auto mechanics are legally required to follow OSHA’s asbestos safety measures.

Do-it-yourself mechanics are not legally required to follow the EPA’s safety recommendations at home. The EPA strongly encourages those who insist on doing this work themselves take additional safety measures.

EPA Recommendations for Home Mechanics

The extensive safety measures involved in DIY automotive work makes it costly. Proper disposal is also important to prevent exposure among those who work in landfills.

Peritoneal mesothelioma survivor Epifanio Figueroa tells The Mesothelioma Center at Asbestos.com that he came into contact with asbestos through both primary and secondary exposure. He says his father’s occupational asbestos exposure and then his own occupational exposures as a home mechanic put him at risk.

Companies manufactured asbestos products for automotive transportation since the early 1900s. Some companies made parts such as brake linings, insulation and gaskets with asbestos until the late 1980s.

Manufacturers of Asbestos Auto Parts

Some imported auto parts currently contain asbestos. The U.S. Geological Survey’s Mineral Commodity Summaries of January 2024 noted, “the exhaust system of a specific type of utility vehicle” and “some vehicle friction products” imported into the U.S. as of 2020 were known to contain asbestos.

OSHA has set safety regulations for professional auto workers. This includes automotive brake and clutch inspection, disassembly, repair and assembly operations. These safety measures describe regulations of work practices to follow. Educating workers on asbestos risks and personal hygiene protocols.

OSHA-Approved Cleaning Methods

Automotive workers in states without administration-approved state plans must follow the regulations set forth in the EPA’s Asbestos Worker Protection Rule. In order for states to obtain approval for their own plans, they must apply for an exemption and, according to the EPA, “…send to the Director of EPA’s Office of Pollution Prevention and Toxics a copy of its asbestos worker protection regulations and a detailed explanation of how your state’s asbestos worker protection plan meets the requirements of

TSCA section 18 (15 U.S.C. 2617).”

The sources on all content featured in The Mesothelioma Center at Asbestos.com include medical and scientific studies, peer-reviewed studies and other research documents from reputable organizations.

Your web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

King, D. (2024, September 4). Asbestos in Automobiles & Transportation. Asbestos.com. Retrieved November 20, 2024, from https://www.asbestos.com/exposure/automobiles/

King, Daniel. "Asbestos in Automobiles & Transportation." Asbestos.com, 4 Sep 2024, https://www.asbestos.com/exposure/automobiles/.

King, Daniel. "Asbestos in Automobiles & Transportation." Asbestos.com. Last modified September 4, 2024. https://www.asbestos.com/exposure/automobiles/.

Mesothelioma Center - Vital Services for Cancer Patients & Families doesn’t believe in selling customer information. However, as required by the new California Consumer Privacy Act (CCPA), you may record your preference to view or remove your personal information by completing the form below.