Rutland Fire Clay Company

Rutland Fire Clay Company made asbestos-containing products from 1900 to 1978. The company was sued by workers who claimed using its products caused them to develop asbestos-related diseases. The company went bankrupt and established a trust fund to handle future claims.

Written by Michelle Whitmer | Edited By Walter Pacheco | Last Update: July 18, 2024

Rutland’s History with Asbestos

Rutland Fire Clay Company was founded in Montpelier, Vermont, in 1883. The first product it sold was a stove lining designed to reduce the buildup of soot and increase a stove’s efficiency.

The company later expanded to make stove polishes, home repair items and construction materials. Many of these products were designed to withstand high temperatures and were manufactured with asbestos because the mineral is naturally heat-resistant.

Rutland is now headquartered in Chapel Hill, North Carolina. Products are made and shipped from Jacksonville, Illinois.

The company focused on controlling creosote, which is a combustible byproduct that can build up in coal and wood-fired chimneys and stoves.

Many Rutland products produced in the early 1900s were designed to reduce soot, which simplified fireplace maintenance. This made Rutland popular when shortages during World War II caused increased usage of wood stoves.

Rutland focused on manufacturing large quantities of construction products, which made using low-cost asbestos a profitable choice. Asbestos was used as filler in the company’s patching compounds and cements, which were designed to withstand high temperatures.

Like other asbestos companies, Rutland has faced tens of thousands of asbestos lawsuits filed by workers who developed asbestos-related diseases after using its products. These suits forced the company into bankruptcy. It was subsequently required to create a trust fund to compensate future victims.

Bankruptcy and Trust Fund

Rutland had 37,000 pending cases and $3 million in assets when it filed for Chapter 11 bankruptcy in October 1999.

In 1999, Rutland’s president, Thomas Martin, testified before Congress. He estimated Rutland’s liability for current and future asbestos claims at $67 million. Martin cited these claims as the reason for the bankruptcy.

The company set up a trust fund in 2000, known as the Rutland Fire Clay Company Asbestos Trust, to handle past and future claims. November 2010 to January 2011 was the last time period for which the trust accepted claims. The trust is currently registered as inactive.

As of 2022, Rutland continues to operate out of its headquarters in North Carolina, with manufacturing and production in the state of Illinois.

Gain access to trust funds, grants and other forms of compensation for you or your loved ones.

Get Help NowAsbestos Litigation Involving Rutland

From 1984 to 1999, 50,000 asbestos-related cases were filed against Rutland. The majority of the lawsuits were filed by workers who used Rutland’s asbestos products on the job.

Two cases demonstrating types of asbestos exposure from Rutland products involved Ethel Scheidel and Kenneth Cobb.

- In a 1997 New York Supreme Court case, Ethel Scheidel filed a claim against Rutland on behalf of her husband, Victor Scheidel. Scheidel encountered asbestos while working as an independent contractor and was later diagnosed with asbestosis.

- In 2001, Owens Corning Fiberglass added Rutland as a party defendant in a case where a pipefitter, Kenneth Cobb, developed asbestosis. Cobb spent 40 years using asbestos insulation and wallboard for refrigeration, air conditioning and heating systems and pneumatic control systems. Cobb received $689,782 in compensatory damages.

Asbestos issues are not the only legal problem Rutland has dealt with in recent years. In 2016, Rutland paid a fine of $1,000 to the state of California for violating health and safety codes when it didn’t properly label its Safe Lite Fire Starter Squares, which had the potential of releasing toxic chemicals into the air.

In 2008, Rutland was fined $10,000 by the California Air Resources Board for distributing its One Match Gelled Fire Starter without proper certification.

Rutland’s Asbestos Products

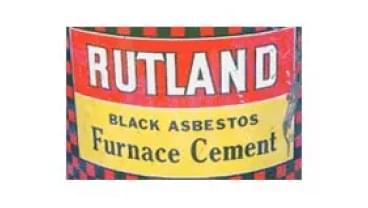

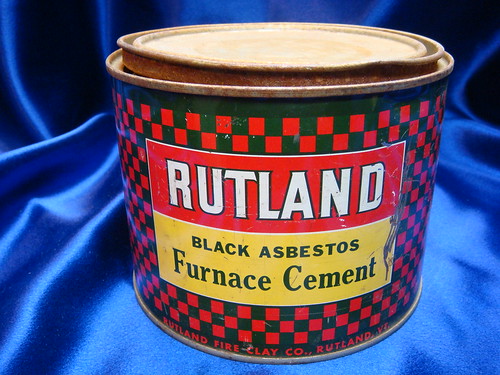

From 1900 to 1978, Rutland manufactured the following asbestos-containing products:

- Rutland Boiler Covering

- Rutland Furnace Cement

- Rutland Ready-Mined Joint Cement

- Rutland Wallboard Joint Cement

- Rutland Roofing Cement No. 4

- Rutland Roofing Cement No. 7

Some of these products contained up to 10% chrysotile asbestos.

Damage to these products can release asbestos dust. Inhaling these fibers repeatedly over time is the primary cause of mesothelioma.

Occupations at Risk of Exposure to Rutland’s Asbestos Products

The following occupations faced risk of exposure to asbestos through Rutland’s products:

- Boiler workers

- Brick masons

- Carpenters

- Construction workers

- Cement workers

- Drywallers

- Roofers

- Rutland employees

Construction workers and mortar and bricklayers who used older asbestos-containing cement products manufactured by Rutland were likely exposed to asbestos.

Rutland made materials with asbestos found in rocks from the Vermont area. Rutland workers preparing these cement products also encountered asbestos exposure.

This Page Contains 8 Cited Articles

The sources on all content featured in The Mesothelioma Center at Asbestos.com include medical and scientific studies, peer-reviewed studies and other research documents from reputable organizations.

- Conrad, D., Vanacek, D., & King, S. (2020). Industrial Minerals of Vermont: 200 Years and Going Strong. Retrieved from https://dec.vermont.gov/geological-survey/resources-energy/minres/ind

- Rutland. (2020). About. Retrieved from https://www.rutland.com/

- Settlement Agreement. (2016, August 30). Rutland Fire Clay Company. Retrieved from https://oag.ca.gov/system/files/prop65/settlements/2016-00659S5205.pdf

- Rand. (2010). Asbestos Bankruptcy Trusts: An Overview of Trust Structure and Activity with Detailed Reports on the Largest Trusts. Retrieved from https://www.rand.org/content/dam/rand/pubs/technical_reports/2010/RAND_TR872.pdf

- California Air Resources Board. (2008, March 17). Rutland Fire Clay Company Case Settles for $10,000. Retrieved from https://ww2.arb.ca.gov/rutland-fire-clay-company-settlement

- Rutland Trust. (2010, October 25). Asbestos Personal Injury Claims Period. Retrieved from http://resasb.org/assets/documents/attltrrfc.pdf

- Town of West Rutland. (1999, June 30). Retrieved from https://archive.org/details/WestRutlandTownReport1999

- Supreme Court of Indiana. (2001, September 10). Owens Corning Fiberglass Corporation versus Cobb. Retrieved from http://caselaw.findlaw.com/in-supreme-court/1472293.html

-

Current Version

-

July 18, 2024Written ByMichelle WhitmerEdited ByWalter Pacheco